Our corporate values

We create added values for our customers.

We work safely.

We offer trust and show appreciation.

We are sustainable.

Brixen (Headquarters): all central functions all processes

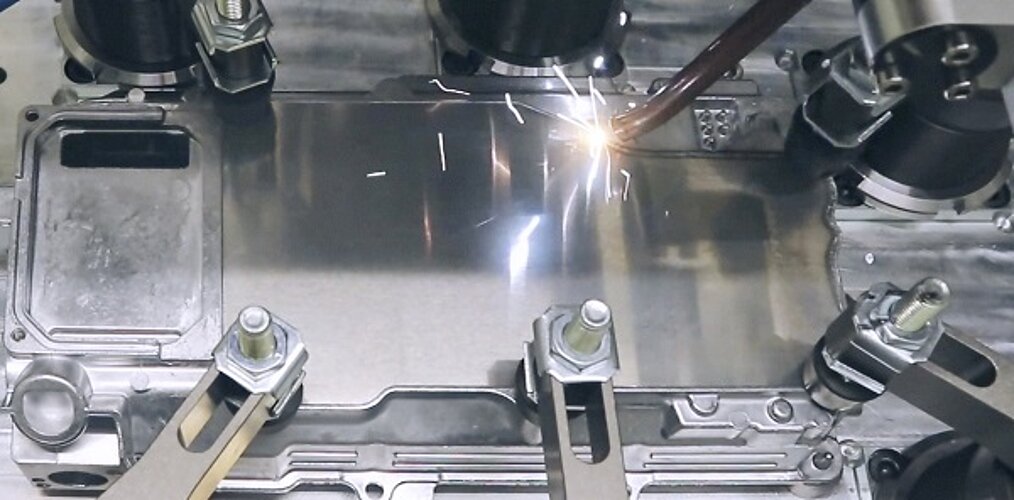

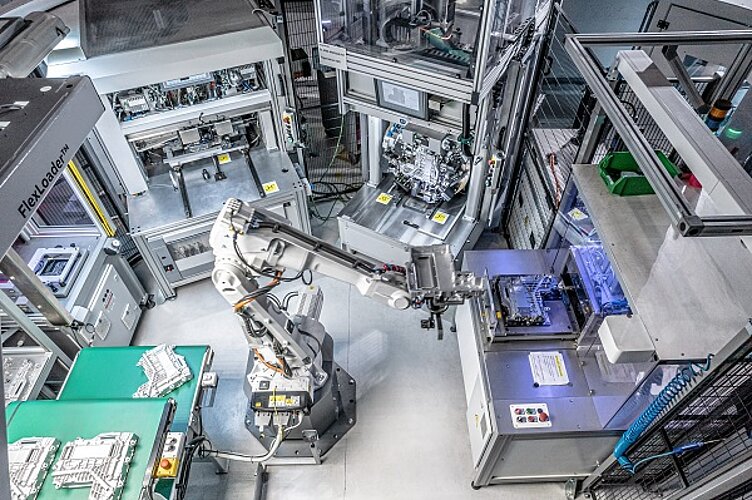

Processes: Casting - deflashing ► Shot blasting and slide grinding ► Mechanical processing ► Washing ► Leakage tests ► Coantings (external partners) ► Assembly lines ► Laser welding ► Laser cleaning / Laser marking ► CT-Scan ► X-Ray ► Clean area ► Residual dirt laboratory ► Microscopic analyses ► Bonding- and adhesion tests

Alupress Tooling: technology center for tools

Processes: 4 CAD workplaces ► 8 CAM workplaces ► 3D printing metal ► Die-sinking EDM system, palletized ► Wire erosion machine ► CNC 3 axis milling centers► 5-axis milling centers, palletized ► HSC Milling ► CNC Lathing ► Roll grinding ► Measuring machine ► Assembly and polishing

Hildurghausen: our production plant in Germany

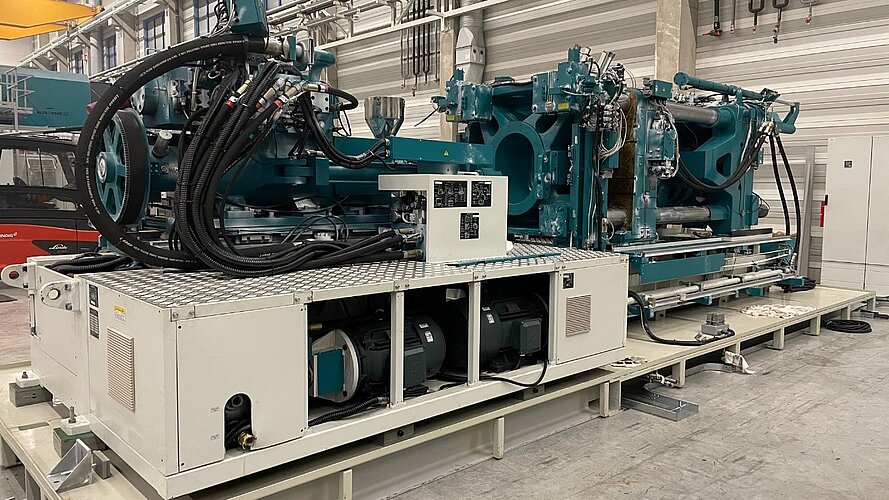

Processes: Casting - deflashing ► Shot blasting / slide grinding ► Machining ► Washing ► Leakage tests ► Coatings (external partners) ► Clean area ► Adhesion tests ► New since 2021: Thixomolding ► New since 2022: 1400t die casting cell

Laurens: our manufacturing location in the USA

Processes: Casting - deflashing ► Shot blasting ► Mechanical processing ► Washing ► Leakage tests ► Coatings (external partners) ► Assembly lines ► Clean area ► Residual dirt laboratory ► Adhesion tests ► CT Scan ► X-Ray

Alupress at a Glance

Learn more about Alupress, our history and our range of services in our corporate brochure or gain a compact overview with the company presentation.

Mission Statement

Our mission statement and corporate values form the foundation of our daily work and commitment. These principles guide us in our efforts to provide excellent services and make a positive contribution to our community and the environment.

Code of Ethics

Alupress has the ambition to create high added value for its customers, to be a preferred employer for its employees and a prominent corporate citizen in society. Achieving this requires utmost integrity and professionalism. Success in our industry depends upon the trust of all our customers, our employees and our suppliers.

With the below Code of Ethics, we solidify this foundation in order to maintain and further expand this trust.

Gender equality policy

Alupress is committed to creating a working environment in which values of diversity, inclusion and gender equality are not only anchored in theory, but also implemented in practice. We believe that a respectful and fair working environment not only promotes the satisfaction and well-being of our employees, but also increases the innovativeness of our company. By developing various strategies and business practices, we strive to ensure equal opportunities and counteract discrimination.

Organizational Model

Professional and proactive risk management plays a key role in our value-oriented corporate management procedures. For this reason, we established an Organisation, Management and Control Model at our Brixen site, pursuant to and for the purposes of implementing Legislative Decree 231/2001. In Italy, this model provides for criminal liability of legal persons and, thus, the company as a whole. This means that in the case of crimes listed under Legislative Decree 231/2001, both the person having committed the crime and the company are held liable.

In order to prevent such crimes being committed, our company conducted specific risk analysis and assessment.