Certifications Automotive Standard - Optical 3D metrology - SPC - Laboratory - Complaints management - Problem-solving methods - CT analyses - Grinding surface joint analyses weld seams

System solutions in best quality

As a full-service partner we accompany our customers from the initial technological idea to the end of production. Thanks to our in-house know-how and specific tools we can provide customers with the best possible help in development consulting and project management. Component and tool simulations, component design or even value stream design round off our offer for the pre-production phase, while our manufacturing processes range from die-casting, surface finishing and machining through to component assembly. There is a constant focus on quality standards in all manufacturing processes.

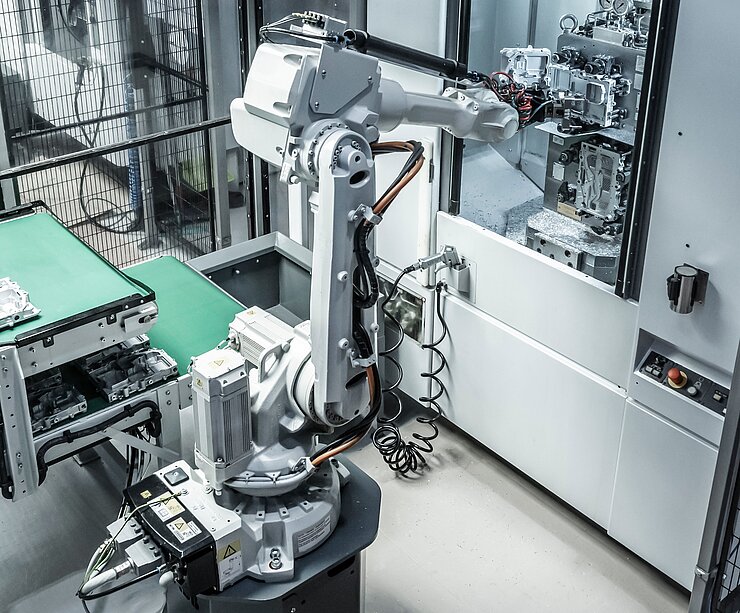

In-house toolmaking

Alupress Tooling is the toolmaking division of the Alupress Group and as such is equipped with state-of-the-art automated machinery.

Our technologically complex tools are manufactured exclusively for the production plants of the Alupress Group: our customers appreciate this independence from third-party suppliers, especially when it comes to deadline-critical tools.

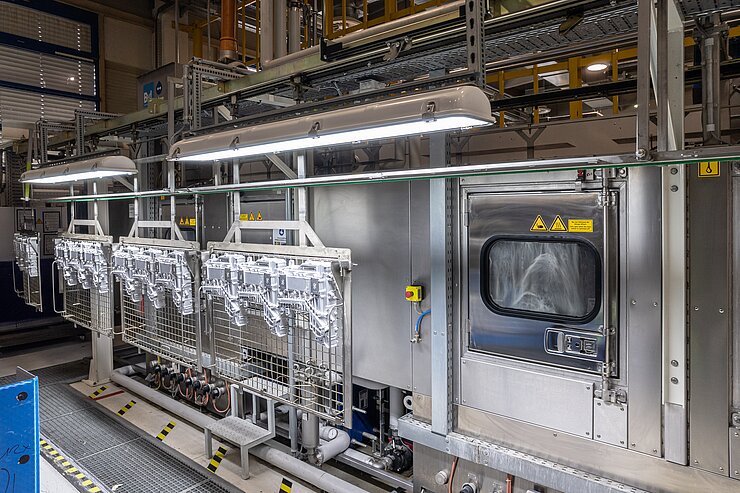

Surface finishing: the starting point for constant component cleanliness

Blasting machines with suitable blasting material remove even the last flaky burrs visible to the eye. The encapsulated vibratory finishing systems give the components their final polish.

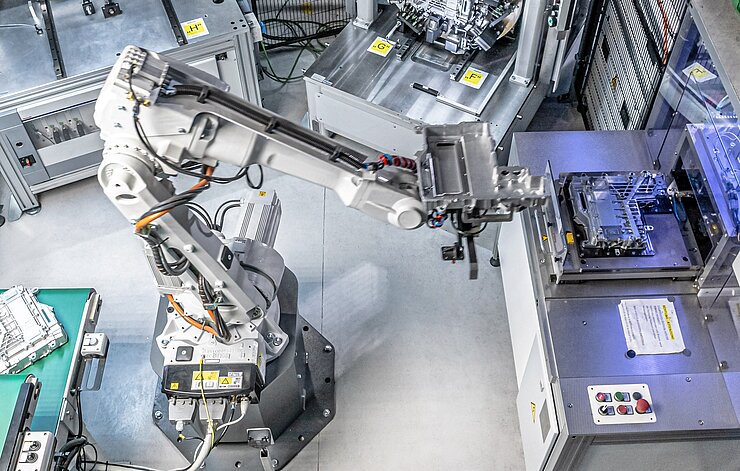

Precision in casting continues in machining

The die cast parts are machined using state-of-the-art production technology in single- or multi-spindle CNC machining centers. Automation and interlinking, both of further production steps and testing, are designed to ensure maximum flexibility at all times.

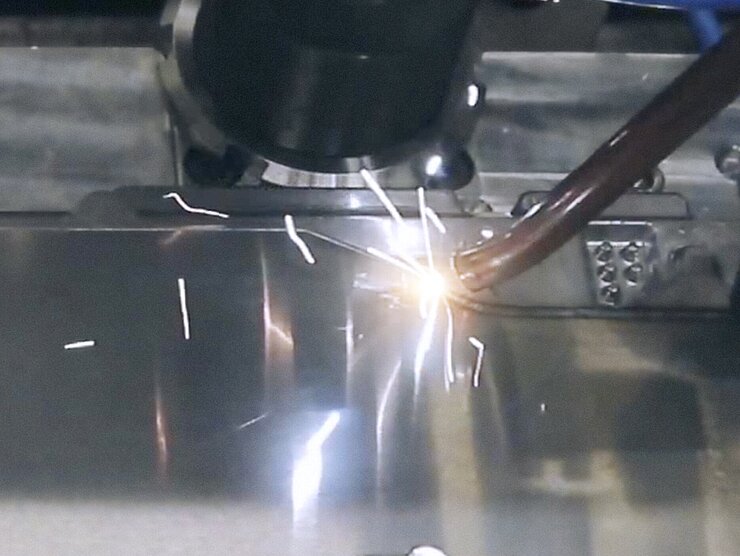

Automated assembly and laser welding as a safe jointing process

The components are further honed on customer-specific assembly lines. Sophisticated jointing processes not only save money on purchased parts and assembly steps: they also reduce environmental impact.

Our newly implemented laser welding process means not only good dimensional stability, but also significant weight savings compared to conventional jointing techniques, such as friction stir welding (FSW). Only after error-free testing on standardized equipment will our components receive a corresponding marking for traceability.

External value creation expands our range of services

Customer value is our top priority. Our supplier management reliably secures both our purchased parts for assembly and outsourced contract manufacturing (e.g. coatings or heat treatment).

Quality and a zero-defect strategy are our top priority

We achieve the highest quality by continuously improving all process steps and areas. Our strict focus on quality is emphasized by our certification to IATF 16949, a standard covering the automotive industry supply chain, as well as our adherence to common industry regulations.

High technical cleanliness

Our automatically process-monitored washing systems meet the latest technological standards. They enable us to produce parts that can be glued, bonded or painted. We use environmentally friendly washing media that are based on water or alcohol.

![[Translate to English:] Bauteil wird im Labor von Alupress gereinigt](/fileadmin/_processed_/d/a/csm_Alupress-2_8065dce85f.jpg)

Laboratory in accordance with international giudelines

Our modern laboratory, set up in accordance with international guidelines for technical cleanliness (VDA 19/ISO 17025), ensures that we can keep our promises to customers. Various laboratory tests permit a qualitative assessment of the processes on the end product, such as the technical cleanliness, film residues or adhesion and bondability.

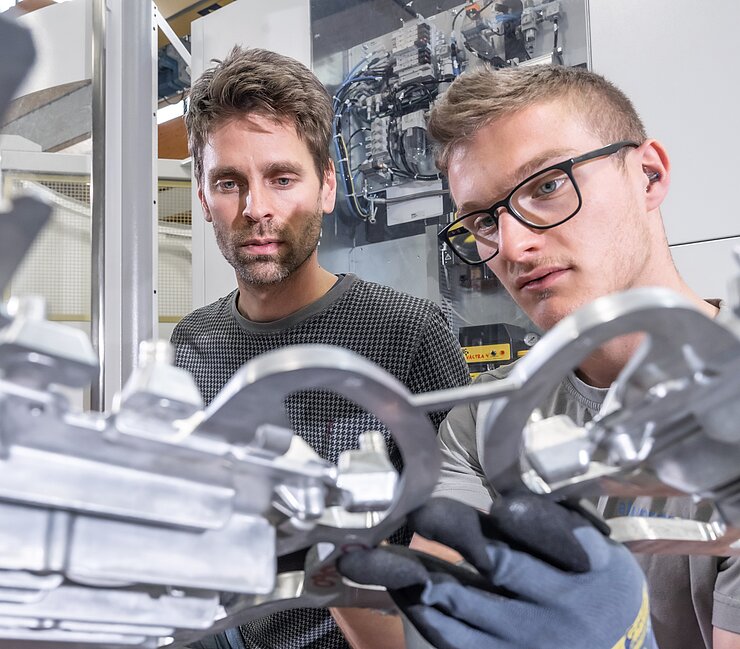

People and know-how

At Alupress, our employees are the people at the very heart of our activities and actions, because they are the guarantee of our success and reputation. We also invest in further training and set high social standards.

Facilities and technologies

We possess the latest production facilities and technologies so as to turn concepts into innovative solutions and products for large-scale series production.

Process technology Aluminum die-casting

Alupress produces aluminum die cast components of the highest precision and quality. In-house simulations before the start of the project, sophisticated tool design and in-house tool production, combined with minimum quantity spraying in the casting process, bring measurable added value for our customers.

This makes it possible to meet even the highest requirements for sealing and component properties such as bonding, painting and adhesion capacity.

Field of application Car

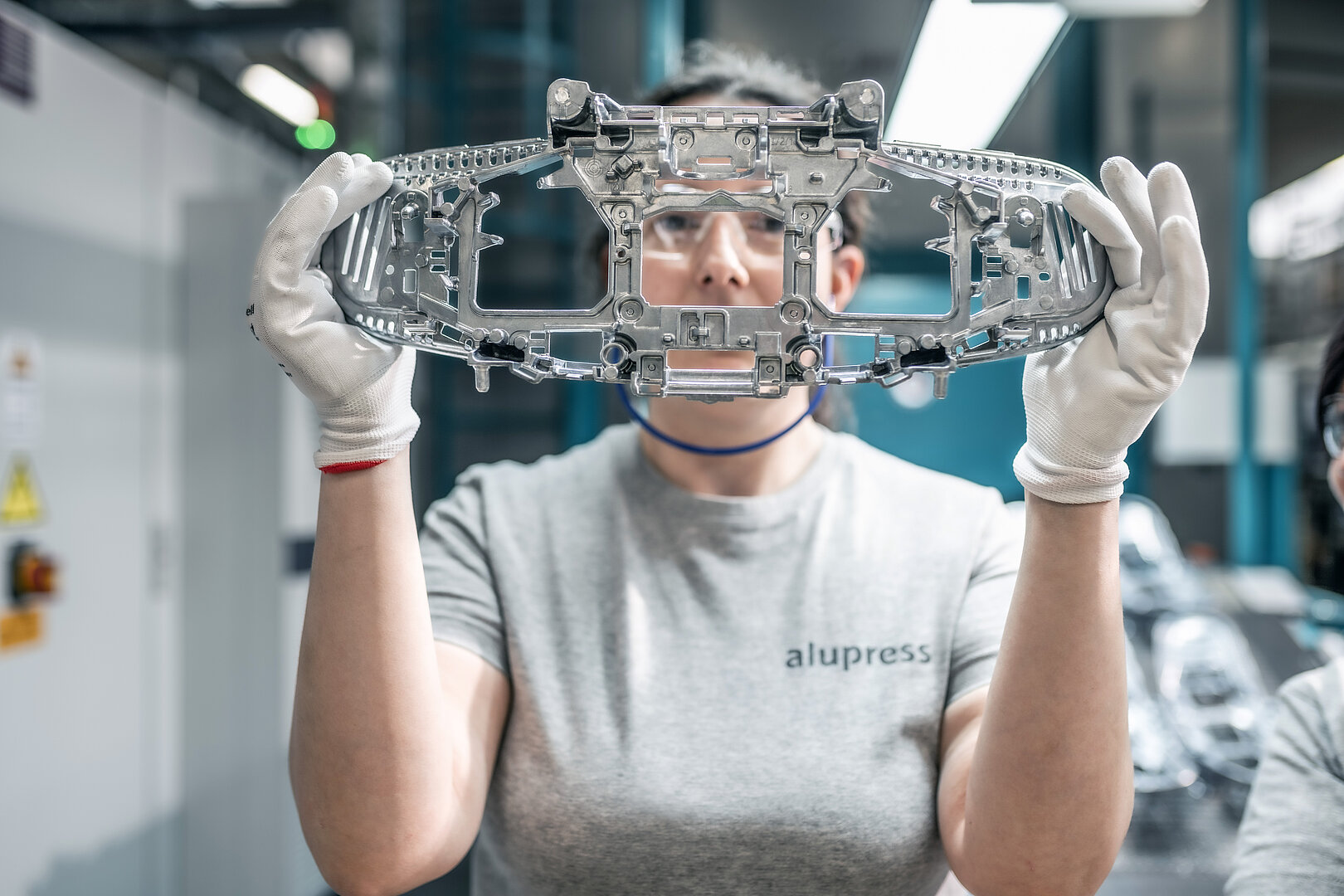

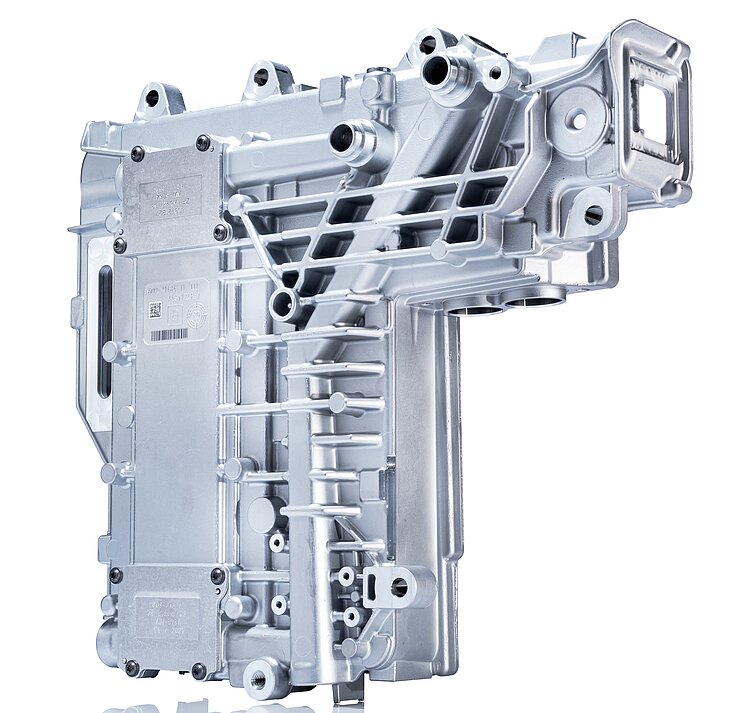

Housing with subassemblies for power electronics in electric vehicles

The illustrated component shows the housing for the power electronics of electric vehicles The power electronics are mounted directly onto the axle and convert the direct current from the battery into alternating current for the electric motor. The power electronics, electric motor and multi-stage gearbox, including differential, are integrated into a highly compact unit.

For this product sector, Alupress produces installation-ready, high-purity components for a power range of 400 – 800 volts. Functional component surfaces are cast and, in addition to the assembly phase, die cast aluminum is also laser-welded. This technology enables savings on assembly parts and costs and, at the same time, reduces component mass, thus contributing to reducing C02.

Field of application Truck

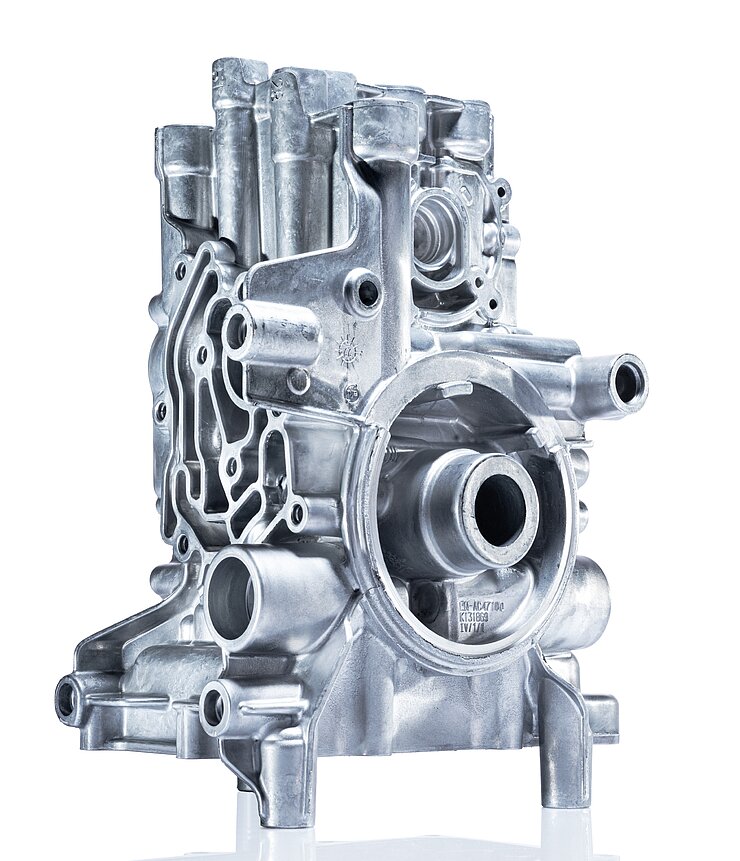

Housing for air circulation in braking systems for trucks and buses

The illustrated component shows the housing for an electronic air dryer with intelligent compressed-air management. Compressed air from the compressor is cleaned, moisture from the braking system is eliminated and oil is separated. This supplies the braking system with compressed air which is suitable to ensure safe braking.

All of these product functions require pressure-tight casting after processing. Mechanically machined surfaces must be free of pores and cavities in order to ensure adequate sealing. Alupress achieves all this without impregnation, thanks to our wide-ranging expertise, the use of all technologies now on the market and intensive collaboration with customers in product development.

Process technology Magnesium thixomolding

Magnesium parts are approx. 33% lighter than aluminum parts of the same volume. For components where weight plays a role, but plastic cannot be used (e.g. on account of thermal conductivity), magnesium is a suitable alternative.

The magnesium thixomolding process makes it possible to produce components even more precisely and with thinner walls than with conventional magnesium die casting. It should also be emphasized that the environmentally harmful protective gas from conventional die casting is completely avoided. This technology also minimises fire risks.

In addition to the massive weight saving, magnesium – like aluminum – offers complete recyclability.

Housing components for a high-performance on-board computer

The thixocasting component illustrated here forms part of a three-part housing for a high-performance computer replacing numerous control units (driver assistance systems, infotainment and computer center for drive and chassis functions).

Magnesium thixomolding is the ideal procedure for complex, thin-walled geometries such as on-board computers or internal components. Given its reduced heat input, thixomolding also leads to a correspondingly longer tool lifespan.

Magnesium – processed by means of thixomolding – is of particular value for interior applications in the automotive sector. This process is however also an attractive solution for other mobility sectors and non-automotive markets.

Stefan Ploner, CTO Alupress